When equipment falters, safety is compromised, or a persistent hum becomes an unwanted soundtrack to your operations, it's not just an inconvenience – it's a drain on your bottom line and potentially a risk to your team. Mastering Maintenance, Safety, and Maximizing Quiet Operation isn't merely about fixing things when they break; it's about orchestrating a symphony of proactive care that ensures peak performance, keeps your people safe, and preserves a productive, peaceful environment.

Imagine a world where your assets consistently perform optimally, unexpected breakdowns are rare, and the background noise of operations fades into a whisper. This isn't a fantasy; it's the tangible result of a well-executed strategy, and it’s well within your reach.

At a Glance: Your Blueprint for Operational Excellence

- Proactive over Reactive: Shift from costly emergency repairs to planned, predictive care.

- Safety is Paramount: Integrate safety protocols into every maintenance task to protect personnel and assets.

- Silence is Golden: Strategically reduce operational noise for improved working conditions and compliance.

- Data Drives Decisions: Leverage technology and data to optimize schedules and predict failures.

- Longevity & Savings: Extend equipment lifespan, cut costs, and boost overall productivity.

- Continuous Improvement: Regularly review and analyze performance to refine your approach.

Why Bother? The Unseen Power of Peak Performance

In today's competitive landscape, operational excellence isn't a luxury – it's a necessity. The triumvirate of robust maintenance, unwavering safety, and intentional noise reduction forms the bedrock of highly efficient, compliant, and thriving operations. Ignoring any one of these pillars can lead to a domino effect of costly downtime, safety incidents, regulatory fines, and a less-than-ideal work environment.

Think about it: equipment that runs smoothly and quietly is inherently safer. It signals a well-cared-for asset operating within its design parameters, reducing stress on components and mitigating risks of sudden failure. This meticulous approach translates directly into tangible benefits you can measure, from extended asset life and significant cost savings to enhanced productivity and an undeniable boost to your team's morale and safety. It's about maximizing your return on investment in every piece of equipment you own.

More Than Just Fixing Things: Understanding Modern Maintenance Approaches

The days of simply waiting for something to break before fixing it are largely over. Modern maintenance is a strategic discipline, with several sophisticated approaches designed to optimize asset performance and reliability.

The Spectrum of Maintenance Strategies

1. Preventing the Inevitable: Preventive Maintenance (PM)

Preventive Maintenance is your first line of defense. It's about routine, scheduled tasks – inspections, cleaning, lubrication, and component replacements – performed at regular intervals, often based on manufacturer recommendations or fixed timeframes. The goal? To prevent failures before they happen.

- Example: Changing the oil in a vehicle every 5,000 miles, regardless of how it's currently running.

- Benefit: Reduces unexpected breakdowns, extends asset life, and keeps costs predictable.

2. Crystal Ball Maintenance: Predictive Maintenance (PdM)

Taking things a step further, Predictive Maintenance utilizes advanced technologies to monitor the condition of your equipment in real-time. By analyzing data from sensors (e.g., vibration analysis, thermal imaging, oil analysis), you can anticipate failures before they occur. This isn't about arbitrary schedules; it's about data-driven foresight.

- Example: Monitoring the vibration signature of a motor to detect early signs of bearing wear, then scheduling replacement just before it fails.

- Benefit: Eliminates unnecessary maintenance, maximizes uptime, and allows for precise scheduling.

3. Condition-Based Maintenance (CBM): The 'Just-in-Time' Approach

Closely related to PdM, Condition-Based Maintenance triggers maintenance only when specific indicators show deterioration or performance decline. It's reactive to condition but proactive in prevention. You're not fixing what isn't broken, but you're also not waiting for total failure.

- Example: A filter change indicator light comes on, signaling reduced airflow, prompting immediate replacement.

- Benefit: Optimizes resource allocation, avoids premature parts replacement, and reduces maintenance costs.

4. The Fire Drill: Corrective Maintenance

Sometimes, despite your best efforts, equipment breaks down. Corrective Maintenance is the reactive response, focusing on restoring functionality as quickly as possible. While sometimes unavoidable, a heavy reliance on corrective maintenance is a clear indicator of underlying issues in your proactive strategies. It's often more costly due to unexpected downtime and rushed repairs.

- Example: A conveyor belt snaps, halting production, requiring immediate repair.

- Benefit: Restores functionality quickly, but ideally, this should be a last resort.

5. Strategic Optimization: Reliability-Centered Maintenance (RCM)

RCM is a sophisticated framework that analyzes asset functions, potential failure modes, and their consequences to optimize maintenance and allocate resources effectively. It asks: "What must be done to ensure that any physical asset continues to do whatever its users want it to do?" This approach balances costs, reliability, and operational requirements, leading to highly efficient and tailored maintenance programs.

- Example: For a critical turbine, RCM might determine that frequent, intrusive inspections are less effective than continuous vibration monitoring combined with an annual shutdown for detailed checks.

- Benefit: Maximizes reliability for critical assets, optimizes resource use, and delivers the best balance of cost and performance.

The Blueprint for Reliability: Navigating the Maintenance Process

Effective maintenance isn't a one-off event; it's a cyclical process built on careful planning and execution. Following a structured process ensures nothing is missed and every effort contributes to overall reliability.

1. Planning: Laying the Groundwork

Before a wrench is turned, meticulous planning is essential. This phase involves:

- Asset Identification: Knowing what you have, its criticality, and its history.

- Schedule Creation: Developing maintenance schedules based on manufacturer recommendations, usage data, or PdM insights.

- Resource Estimation: Determining the necessary time, labor (skilled technicians), materials (spare parts, consumables), and tools.

- Safety Procedures: Preparing specific safety protocols for each task, including Lockout/Tagout (LOTO) requirements.

2. Scheduling: Orchestrating the Work

With a plan in place, scheduling assigns the specifics:

- Date & Time: Setting precise dates and times for tasks.

- Technician Allocation: Assigning qualified personnel to each job.

- Equipment Availability: Ensuring the asset is available for maintenance, coordinating with operations to minimize disruption. This might mean scheduling during off-peak hours or planned shutdowns.

3. Execution: Getting the Job Done Right

This is where the actual work happens. Technicians perform inspections, servicing, repairs, and replacements, strictly adhering to checklists and safety protocols. Quality control is paramount during this stage. Remember, a job done correctly the first time prevents needing to do it again soon.

4. Documentation: The Memory of Your Machines

Every completed task, every part replaced, every observation made – all of it must be meticulously recorded. Good documentation supports:

- Compliance: Meeting industry standards and regulatory requirements.

- Cost Tracking: Understanding maintenance expenditures.

- Asset History: Building a comprehensive record that informs future decisions.

- Troubleshooting: Aiding technicians in diagnosing recurring issues.

5. Review & Analysis: Learning and Improving

The final, crucial phase turns data into wisdom. Analyzing maintenance records and performance data helps you:

- Identify Trends: Spot recurring failures or underperforming assets.

- Optimize Schedules: Refine PM frequencies or PdM thresholds.

- Make Informed Decisions: Determine when to upgrade assets, retrain staff, or adjust procedures.

- Drive Continuous Improvement: Constantly refine your maintenance strategy for better results.

Safety First, Always: Building an Accident-Resistant Culture

Maintenance work inherently carries risks. Integrating safety into every facet of your maintenance program isn't just a regulatory requirement; it's an ethical imperative and a cornerstone of operational excellence.

Key Safety Pillars in Maintenance

- Risk Assessment: Before any task, identify potential hazards (electrical, mechanical, chemical, ergonomic) and implement controls.

- Personal Protective Equipment (PPE): Ensure all personnel have and correctly use appropriate PPE for the task – hard hats, safety glasses, gloves, hearing protection, fall arrest systems, etc.

- Lockout/Tagout (LOTO): This critical procedure ensures hazardous energy sources are isolated and rendered inoperable before maintenance work begins, preventing accidental startup and protecting workers.

- Confined Space Entry: Establish strict protocols for entering confined spaces, including atmospheric monitoring, ventilation, and rescue plans.

- Working at Heights: Implement fall protection measures and training for any work performed at elevation.

- Competence and Training: Ensure all maintenance personnel are fully trained and competent in safety procedures, equipment operation, and specific task requirements. Regular refreshers are vital.

- Emergency Preparedness: Have clear emergency response plans, including first aid, fire suppression, and evacuation procedures, readily accessible and understood by all.

A culture of safety means everyone, from the newest technician to senior management, actively champions and adheres to safety protocols. It's about protecting your greatest asset: your people.

Hushing the Hums: Strategies for Maximizing Quiet Operation

Noise pollution is more than just an annoyance; it's a significant health hazard, contributing to stress, hearing loss, and reduced productivity. Maximizing quiet operation is an often-overlooked aspect of peak performance, improving workplace safety, comfort, and compliance.

How to Silence Your Operations

- Source Selection: When procuring new equipment, prioritize models designed for quiet operation. Manufacturers are increasingly offering low-noise options for everything from industrial machinery to portable generators. For instance, when considering backup power, it's worth taking the time to explore quiet portable generators to see how advancements in design can significantly reduce operational noise.

- Regular Maintenance & Lubrication: This is foundational. Well-maintained machinery makes less noise.

- Lubrication: Properly lubricated bearings, gears, and moving parts reduce friction and, consequently, noise.

- Tightening: Loose components rattle. Regularly check and tighten bolts, screws, and mounts.

- Alignment & Balance: Misaligned shafts or unbalanced rotating parts (like fans or pump impellers) generate significant vibration and noise. Precision alignment and balancing can dramatically quiet an operation.

- Vibration Dampening: Noise is often transmitted through structural vibrations.

- Isolation Mounts: Use rubber pads, springs, or specialized vibration isolators under noisy equipment (motors, compressors, pumps) to prevent vibration from transferring to floors and walls.

- Flexible Connections: Use flexible hoses or connectors in piping and ductwork to absorb vibrations before they travel further.

- Acoustic Enclosures & Barriers:

- Enclosures: Custom-built acoustic enclosures or sound-attenuating hoods can significantly contain noise at the source. These typically feature sound-absorbing materials and careful ventilation.

- Barriers: Sound walls or panels can block noise pathways between a noisy area and a quieter one.

- Sound Absorbing Materials:

- Wall/Ceiling Panels: Install acoustic panels on walls and ceilings in noisy environments to absorb sound reflections and reduce reverberation.

- Floor Coverings: Heavy, sound-absorbing floor materials can also help reduce noise transmission.

- Strategic Placement:

- Locate the noisiest equipment away from workspaces or sensitive areas.

- Orient noisy equipment so that its primary sound emission direction points away from personnel.

- Maintenance of Exhaust & Intake Systems: Fans, blowers, and exhaust systems can be major noise culprits. Ensure they are clean, properly sized, and their ducts are free of obstructions. Installing silencers or mufflers on air intakes and exhausts can also be highly effective.

By proactively addressing noise, you're not only creating a more compliant and pleasant working environment but also often identifying underlying mechanical issues that, if left unaddressed, could lead to costly breakdowns.

The Digital Edge: How Technology Transforms Maintenance

The digital revolution has profoundly reshaped maintenance and reliability. Technology isn't just an aid; it's a core enabler of the most effective strategies.

Smart Tools for Smarter Maintenance

- Computerized Maintenance Management Systems (CMMS): These indispensable software platforms centralize all maintenance data – work orders, asset histories, inventories, schedules, and costs. A robust CMMS automates processes, tracks performance, and provides invaluable reports, moving you from reactive chaos to proactive control.

- Internet of Things (IoT) & Sensors: IoT devices embedded in equipment collect real-time data on temperature, vibration, pressure, current, and more. This constant flow of information feeds into condition monitoring systems.

- Artificial Intelligence (AI) & Machine Learning (ML): AI algorithms analyze the vast datasets collected by IoT sensors, identifying subtle patterns that precede equipment failure. This is the intelligence behind advanced Predictive Maintenance, moving beyond simple thresholds to complex failure prediction.

- Predictive Analytics: This discipline uses historical data, statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes. In maintenance, it means foreseeing equipment failure with increasing accuracy.

- Digital Twins: A virtual model of a physical asset, system, or process. Digital twins receive real-time data from their physical counterparts, allowing for simulations, performance monitoring, and predictive failure analysis in a risk-free environment.

- Remote Monitoring: Technologies that allow maintenance teams to monitor equipment performance and condition from a centralized location, often off-site. This enhances responsiveness, reduces travel time, and enables continuous oversight of distributed assets.

Integrating these technologies allows organizations to move from reactive and scheduled maintenance to a truly condition-based and predictive approach, significantly boosting reliability and reducing costs.

Beyond the Basics: Advanced Strategies & Best Practices

To truly excel, you need to embed reliability into the fabric of your operations.

Strategic Reliability Best Practices

- Prioritize Critical Assets: Not all equipment is equally important. Use tools like Failure Modes and Effects Analysis (FMEA) to identify your most critical assets – those whose failure would have the greatest impact on safety, production, or cost. Focus your most robust maintenance strategies (like PdM and RCM) and resources on these vital machines.

- Invest in Training & Workforce Development: Your maintenance team is your most valuable asset. Invest in comprehensive training covering technical skills, CMMS usage, advanced diagnostic techniques, and, crucially, safety protocols. Foster a culture of continuous learning and problem-solving.

- Standardize Operating Procedures (SOPs): Implement clear, step-by-step SOPs for all critical maintenance tasks. This ensures consistency, reduces errors, simplifies training for new staff, and helps ensure regulatory compliance.

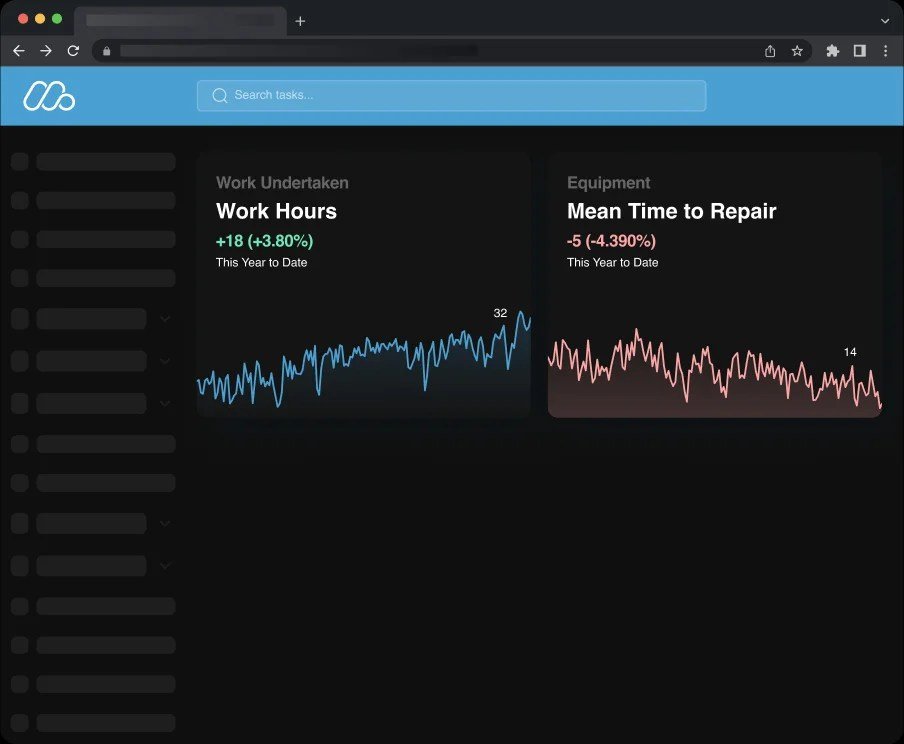

- Monitor Key Performance Indicators (KPIs): "What gets measured gets managed." Track metrics to gauge your maintenance effectiveness:

- Mean Time Between Failures (MTBF): How long equipment runs before breaking down. Higher is better.

- Mean Time To Repair (MTTR): How long it takes to fix something. Lower is better.

- Overall Equipment Effectiveness (OEE): A composite measure of availability, performance, and quality. Aim for high OEE.

- Maintenance Cost per Asset: Track costs to identify areas for efficiency.

- Foster Robust Communication: Maintenance doesn't operate in a vacuum. Ensure strong communication channels across departments – operations, safety, procurement, finance. This aligns schedules, coordinates activities, and improves overall reporting and strategic decision-making. Operations needs to know when maintenance is happening, and maintenance needs to understand production demands.

Common Hurdles & How to Clear Them

Even with the best intentions, implementing a world-class maintenance, safety, and quiet operation program faces challenges.

- Budget Constraints: "We can't afford that advanced system."

- Solution: Frame maintenance as an investment, not an expense. Quantify the cost savings from reduced downtime, extended asset life, and avoided emergency repairs. Start small with high-impact initiatives and demonstrate ROI to secure further funding.

- Resistance to Change: "We've always done it this way."

- Solution: Involve stakeholders early. Communicate the benefits clearly and demonstrate how new processes make jobs easier and safer. Provide thorough training and celebrate early successes.

- Skill Gaps: "Our team isn't trained for predictive maintenance."

- Solution: Invest in targeted training programs. Partner with external experts for specialized tasks. Consider upskilling existing staff or strategically hiring for new capabilities.

- Data Overload & Silos: "We have too much data, but it's not useful."

- Solution: Implement a robust CMMS or EAM (Enterprise Asset Management) system to centralize and analyze data. Focus on key KPIs. Ensure data integration across different systems for a holistic view.

- Lack of Management Buy-in: "Leadership doesn't see the value."

- Solution: Present clear business cases, focusing on financial benefits (cost savings, ROI), safety improvements, and competitive advantages. Use industry benchmarks to show what's possible.

Your Action Plan for Uninterrupted Excellence

Achieving peak performance through superior maintenance, safety, and quiet operation is not a destination but a continuous journey of improvement. It demands commitment, strategic investment, and a cultural shift towards proactive care.

Start by assessing your current state. Where are your biggest pain points – frequent breakdowns, safety incidents, excessive noise, or budget overruns? Then, pick one area to focus on first, perhaps by implementing a robust PM schedule for your most critical assets, or conducting a noise audit to pinpoint major sources.

Leverage technology where it makes sense, even if it's just starting with a basic CMMS to get your data in order. Most importantly, empower your team with the right training and tools, fostering an environment where safety is non-negotiable and efficiency is celebrated.

The ultimate reward is an operation that runs like a well-oiled, whisper-quiet machine: safe, reliable, productive, and profitable. It’s an investment that pays dividends, not just in dollars and cents, but in the peace of mind that comes with operational excellence.